The Essential Guide to Pipe Relining: Benefits and Process

Understanding Pipe Relining

Pipe relining has emerged as a revolutionary technique in plumbing, offering a more efficient and less intrusive method for repairing damaged pipes. This guide delves into the essential benefits and processes involved in pipe relining, providing valuable insights for homeowners and businesses in Australia.

Hard Water Plumbing Impact: What is Pipe Relining?

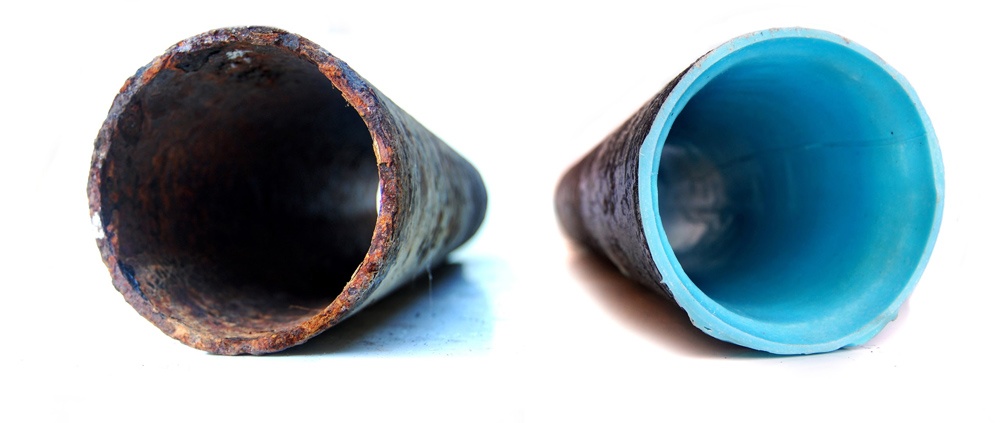

Pipe relining, also known as trenchless pipe repair, is a method that involves repairing existing pipes without the need for extensive digging. This process creates a new pipe within the old one using a special resin that hardens and forms a durable, long-lasting solution.

Benefits of Pipe Relining in Plumbing Systems

- Minimally Invasive

Traditional pipe repair methods often require significant excavation, which can be disruptive and costly. Pipe relining, however, is minimally invasive, reducing the need for digging up landscapes, driveways, or floors. This not only saves time and money but also preserves the aesthetic of your property.

- Cost-Effective

While the initial cost of pipe relining might seem higher than traditional methods, it is often more cost-effective in the long run. The reduced need for excavation and restoration work significantly lowers the overall expense. Additionally, the durable nature of the relined pipes means fewer repairs and replacements are needed over time.

- Durable and Long-Lasting

Pipe relining materials are designed to last. The resin used in the process creates a new pipe within the old one, which is resistant to corrosion and root intrusion. This durability ensures that the pipes can last for decades, providing a long-term solution to plumbing system issues.

- Quick and Efficient

Pipe relining can often be completed within a day, depending on the extent of the damage and the length of the pipes. This efficiency minimises downtime and disruption, making it an ideal solution for both residential and commercial properties.

- Environmentally Friendly

By reducing the need for excavation, pipe relining is also an environmentally friendly option. It minimises the disturbance to the surrounding soil and vegetation, reducing the environmental impact of the repair work.

The Pipe Relining Process for Plumbing Fixtures

Step 1: Inspection and Diagnosis

The first step in the pipe relining process is a thorough inspection using CCTV cameras. This allows plumbers to identify the exact location and extent of the damage within the pipes. The footage provides a clear view of the interior, helping to diagnose issues such as cracks, leaks, or blockages.

Step 2: Cleaning the Pipes

Before relining can begin, the pipes must be cleaned thoroughly to remove any debris, roots, or mineral buildup that could interfere with the relining process. This is typically done using high-pressure water jets or mechanical cutting tools. A clean surface ensures the resin adheres properly to the existing pipe.

Step 3: Measuring and Preparing the Liner

Once the pipes are clean, the next step involves measuring the length and diameter of the damaged section. A liner, coated with a special resin, is then prepared to match these measurements. The resin is crucial as it will harden and form the new pipe within the old one.

Step 4: Inserting the Liner

The prepared liner is inserted into the damaged pipe using an inversion drum or a winch. Air or water pressure is used to push the liner through the pipe, ensuring it reaches the entire damaged section. The liner is then inflated, pressing it against the interior walls of the existing pipe.

Step 5: Curing the Resin

After the liner is in place, the resin needs to be cured. This can be done using hot water, steam, or UV light, depending on the type of resin used. The curing process hardens the resin, creating a strong, seamless new pipe within the old one.

Step 6: Final Inspection

Once the resin has cured, a final inspection is conducted using CCTV cameras. This ensures that the relining has been successful and that the new pipe is properly formed and free of defects. The inspection confirms the quality and integrity of the repair work.

Common Applications of Pipe Relining for Decreased Water Pressure

Residential Plumbing

Pipe relining is commonly used in residential settings to repair damaged sewer and stormwater pipes. Homeowners benefit from the minimal disruption and long-lasting results, ensuring their plumbing systems function efficiently.

Commercial Plumbing

For commercial properties, pipe relining offers a practical solution for maintaining and repairing extensive plumbing networks. Businesses can avoid costly disruptions and downtime, making it a preferred choice for many commercial establishments.

Municipal and Industrial Uses

Municipal and industrial applications, including those involving the municipal water supply, also benefit from pipe relining, particularly in areas where excavation would be highly disruptive or impractical. The durability and efficiency of pipe relining make it suitable for large-scale infrastructure projects.

Key Considerations and Limitations of Mineral Buildup

Suitability of Existing Pipes

While pipe relining is a versatile solution, it may not be suitable for all types of pipe damage. Severely collapsed pipes or those with extensive structural damage might require traditional repair methods. Pipes with high mineral content from hard water may require additional cleaning steps before relining can be effective. A professional assessment is essential to determine the suitability of pipe relining for your specific situation.

Cost Factors

The cost of pipe relining can vary based on several factors, including the length and diameter of the pipes, the extent of the damage, and the specific resin used. While generally cost-effective, it’s important to obtain a detailed quote and understand the potential costs involved.

Choosing a Reputable Plumber

The success of a pipe relining project heavily depends on the expertise and experience of the plumber. Choosing a reputable plumbing service with a proven track record in pipe relining ensures high-quality results and long-lasting repairs.

Conclusion

Pipe relining offers a modern, efficient, and durable solution for repairing damaged pipes without the need for extensive excavation. Its numerous benefits, including minimal disruption, cost-effectiveness, and long-lasting results, make it an ideal choice for homeowners, businesses, and municipalities. By understanding the process and key considerations, you can make informed decisions about using pipe relining to address your plumbing needs. For more information or to schedule a consultation, contact us. Additionally, if you need immediate assistance, our emergency plumber Sydney service is available 24/7.